Our Products

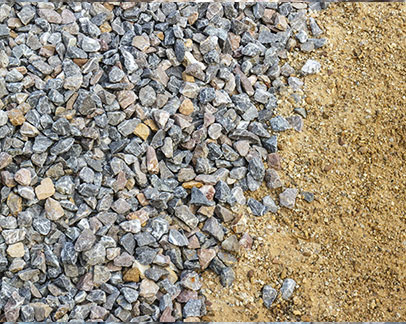

Crushed Stone

Limestone, dolomite and granite are the most common types of rock processed into crushed stone. Limestone and dolomite account for 71% all crushed stone; granite makes up 15%. The remainder is sandstone, quartzite and other types of rock. It is produced by crushing quarried rock, then screening it to sizes appropriate for the intended use.

Limestone, dolomite and granite are the most common types of rock processed into crushed stone. Limestone and dolomite account for 71% all crushed stone; granite makes up 15%. The remainder is sandstone, quartzite and other types of rock. It is produced by crushing quarried rock, then screening it to sizes appropriate for the intended use.

Limestone is the most common used crushed stone because it’s widely available and suitable for many different applications. It’s the primary ingredient of cement, the main component of asphalt and concrete, and a base material for highways, rural roads and buildings. Applications outside of construction include agricultural lime for soil neutralization. Production of crushed stone has three stages: Primary crushing to break down the stone to a manageable size; secondary and tertiary crushing to render the rocks into sizes specific to their applications; and screening to separate the crushed stone for further processing or for finished products sizes.

Crushed Stone

Limestone, dolomite and granite are the most common types of rock processed into crushed stone. Limestone and dolomite account for 71% all crushed stone; granite makes up 15%. The remainder is sandstone, quartzite and other types of rock. It is produced by crushing quarried rock, then screening it to sizes appropriate for the intended use.

Limestone is the most common used crushed stone because it’s widely available and suitable for many different applications. It’s the primary ingredient of cement, the main component of asphalt and concrete, and a base material for highways, rural roads and buildings. Applications outside of construction include agricultural lime for soil neutralization. Production of crushed stone has three stages: Primary crushing to break down the stone to a manageable size; secondary and tertiary crushing to render the rocks into sizes specific to their applications; and screening to separate the crushed stone for further processing or for finished products sizes.

Sand and Gravel

Natural sand and gravel is usually dug or dredged from a pit, bank, river, lake or seabed. In most cases, minimal processing is needed beyond washing and screening the material to separate it by particle size. While they share common uses and applications, crushed stone and sand and gravel differ in their physical properties and production.

Natural sand and gravel is usually dug or dredged from a pit, bank, river, lake or seabed. In most cases, minimal processing is needed beyond washing and screening the material to separate it by particle size. While they share common uses and applications, crushed stone and sand and gravel differ in their physical properties and production.

Sand and gravel are naturally occurring materials shaped by the water in which it is formed and transported. Erosion and weathering render the stone round instead of angular. This shape is the principle difference between crushed stone and sand and gravel. About 44% of construction sand and gravel is used as concrete aggregates, 25% for road base, and 13% as aggregate for asphalt. The remainder is used for base, fill and other applications.

Sand and Gravel

Natural sand and gravel is usually dug or dredged from a pit, bank, river, lake or seabed. In most cases, minimal processing is needed beyond washing and screening the material to separate it by particle size. While they share common uses and applications, crushed stone and sand and gravel differ in their physical properties and production.

Sand and gravel are naturally occurring materials shaped by the water in which it is formed and transported. Erosion and weathering render the stone round instead of angular. This shape is the principle difference between crushed stone and sand and gravel. About 44% of construction sand and gravel is used as concrete aggregates, 25% for road base, and 13% as aggregate for asphalt. The remainder is used for base, fill and other applications.

Recycled Concrete Aggregates

Go Green! Weber Materials provides several eco-friendly initiatives to recycle old concrete. At most locations, we offer crushed recycled concrete in a variety of gradations which makes for an excellent base material for slabs and concrete drives. Additionally, Weber provides economical fill material to get your site on grade.

Go Green! Weber Materials provides several eco-friendly initiatives to recycle old concrete. At most locations, we offer crushed recycled concrete in a variety of gradations which makes for an excellent base material for slabs and concrete drives. Additionally, Weber provides economical fill material to get your site on grade.

More recently another type of aggregate has emerged: recycled concrete aggregate (RCA) which is produced by crushing concrete reclaimed from concrete buildings, slabs, bridge decks, demolished highways, and other structures. Aging infrastructure, scarce landfill space, cost savings and environmental benefits all fuel the growing demand for concrete recycling.

Concrete from demolition sites is crushed, processed to remove metal such as reinforcing steel, and then screened to appropriate sizes. The crushed concrete is then re-used as aggregate for fill, road base or even new concrete – many of the same applications as conventional crushed stone.

One approach is to haul the concrete debris to a permanent recycling facility or quarry for crushing and screening. We accept material to our recycle yards directly providing you savings from transport and fees associated with traditional landfills.

Recycled concrete currently supplies about 5% of aggregate use. The bulk of recycled aggregates – about 68 % – is used as road base. The remainder is used for new concrete mixes (6%), asphalt (9%) and fill.

Recycling concrete features both cost savings and environmental benefits:

- Reduced disposal of concrete in landfill

- Conservation of natural resources

- Reduced cost for raw materials

- Energy savings from less processing and transportation

Recycled Concrete Aggregates

Go Green! Weber Materials provides several eco-friendly initiatives to recycle old concrete. At most locations, we offer crushed recycled concrete in a variety of gradations which makes for an excellent base material for slabs and concrete drives. Additionally, Weber provides economical fill material to get your site on grade.

More recently another type of aggregate has emerged: recycled concrete aggregate (RCA) which is produced by crushing concrete reclaimed from concrete buildings, slabs, bridge decks, demolished highways, and other structures. Aging infrastructure, scarce landfill space, cost savings and environmental benefits all fuel the growing demand for concrete recycling.

Concrete from demolition sites is crushed, processed to remove metal such as reinforcing steel, and then screened to appropriate sizes. The crushed concrete is then re-used as aggregate for fill, road base or even new concrete – many of the same applications as conventional crushed stone.

One approach is to haul the concrete debris to a permanent recycling facility or quarry for crushing and screening. We accept material to our recycle yards directly providing you savings from transport and fees associated with traditional landfills.

Recycled concrete currently supplies about 5% of aggregate use. The bulk of recycled aggregates – about 68 % – is used as road base. The remainder is used for new concrete mixes (6%), asphalt (9%) and fill.

Recycling concrete features both cost savings and environmental benefits:

- Reduced disposal of concrete in landfill

- Conservation of natural resources

- Reduced cost for raw materials

- Energy savings from less processing and transportation

Aggregate Sizing

Fine

Fine crushed stone aggregates consist of particle sizes that are typically less than 3/8-inch (9 mm). Fine aggregates are used in asphalt, concrete, backfill, construction and specialty applications.

Common Uses

- Concrete

- Asphalt

- Backfill and bedding materials

- Skid resistance on ice or snow

- Agricultural-lime (Ag-lime)

- Stabilized earth or reinforced soils

Sizes and Designations

Common designations include, but are not limited to: Concrete Sand, Asphalt Sand, Manufactured Sand (Man Sand), Dry & Washed Screening

Coarse

Coarse aggregates consist of gravel, crushed stone or recycled concrete with particle sizes of ranging from 3/8-inch to 1.5 inches. Coarse aggregates are used in a wide range of construction applications, notably in concrete and asphalt mixes.

Common Uses

- Concrete aggregate

- Asphalt aggregate

- Drainage stone

- Seal coat chips for roadways

- Stone roads and driveways

- Road base / base stone

- Backfill

Sizes and Designations

Common designations include, but are not limited to: #4, #467, #57, #6, #67, #7, #8, #89, #9

Basic Coarse

Dense-graded base coarse refers to aggregates with a range of particle sizes, usually 1-1/2-inch and smaller, that produce a dense layer of stone with a minimum number of voids. Primarily uses include pavement and construction applications.

Common Uses

- Foundation for asphalt pavement

- Foundation for concrete pads and pavements

- Unpaved roads and shoulders

- Backfill for pipe and underground utilities

- Cement-treated base

Sizes and Designations

Common designations include, but are not limited to: Base, Subbase, Dense Graded Base, Crushed Stone Base, Graded Aggregate Base (GAB), Aggregate Base Course (ABC), Macadam Base Course (MBC)

Rip-Rap

Rip-Rap is large pieces of crushed stone (4 inches or larger) typically used to protect shorelines and slopes from erosion and runoff. Architectural and landscaping applications are also common.

Common Uses

- Erosion control

- Runoff protection

- Slope stability

- Landscaping

- Architectural applications

- Gabion baskets

Sizes and Designations

Sizes and designations vary by location due to governing agency requirements. Contact a sales representative for more information.

Fine Gravel

Fine aggregates consist of natural sand. Particle sizes are usually less than 3/8-inch (9 mm). Typical uses include in concrete, mortar, asphalt, backfill and construction applications.

Common Uses

- Concrete

- Mortar sand

- Asphalt

- Drainage courses under pavements

- Filter courses

- Backfill and bedding materials

- Skid resistance on ice or snow

- Stabilized earth or reinforced soils

Sizes and Designations

Common designations include, but are not limited to: Concrete Sand, Asphalt Sand, Masonry Sand and Fill Sand

Coarse Gravel

Natural Coarse aggregates consist of particle sizes of ranging from 3/8-inch to 1.5 inches. Natural coarse aggregates are used in construction applications, notably in concrete and asphalt mixes.

Common Uses

- Concrete aggregate

- Asphalt aggregate

- Drainage stone

- Pea gravel

- Seal coat for roadways

- Backfill

Sizes and Designations

Common designations include, but are not limited to: #4, #467, #57, #6, #8, #89, #9

Basic Coarse Gravel

Dense-graded base course refers to aggregates with a range of particle sizes, usually 1-1/2-inch and smaller, that produce a dense layer of stone with a minimum amount of voids. Primarily uses include pavement and construction applications.

Common Uses

- Foundation for asphalt pavement

- Foundation for concrete pads and pavements

- Unpaved roads and shoulders

- Backfill for pipe and underground utilities

- Cement-treated base

Sizes and Designations

Common designations include, but are not limited to: Base, Subbase, Dense Graded Base

Specialty Products

Aggregates fulfill specialized functions outside of construction, such as industrial processes and household and landscaping uses.

Common Uses

- Landscaping stones

- Golf course sand for bunkers

- Playground sand

- Roofing gravel

- Metallurgical gravel

- Thermal backfill

- Filter courses for septic systems

Sizes and Designations

Sizes and designations vary by location due to governing agency requirements and/or application. Contact a sales representative for more information.

Recycled Concrete Coarse

Recycled concrete aggregates (RCA) consist of particles with sizes ranging from 3/8-inch to 1.5 inches. Typical uses include concrete coarse aggregate and construction applications.

Common Uses

- Concrete aggregate

- Drainage stone

- Stone roads and driveways

- Road base

- Backfill

Sizes and Designations

Sizes and designations vary. Contact a representative for more information.